Selecting a custom gearbox manufacturer can make or break your industrial operations. The wrong choice leads to costly downtime, frequent repairs, and frustrated production schedules. The right partner delivers reliable performance, expert support, and peace of mind for years to come.

With dozens of gearbox manufacturers in the USA claiming to offer the best custom gearing solutions, how do you separate genuine expertise from marketing promises? The answer lies in understanding what truly matters when evaluating potential partners.

This guide walks you through the essential factors that distinguish exceptional custom gearbox manufacturers from the rest. You’ll learn what questions to ask, which capabilities to prioritize, and how to identify a manufacturer that can meet your specific operational needs.

Understanding Your Custom Gearbox Requirements

Before reaching out to any gearbox manufacturers in the USA, clarity about your specific needs saves time and ensures better outcomes. Different industries demand different specifications, and understanding these requirements helps narrow your search effectively.

Defining Your Application Parameters

Custom engineered gears require precise specifications. Consider your torque requirements, operating speed, environmental conditions, and space constraints. Mining operations need different gearing solutions than hydroelectric facilities, even though both might require high-torque applications.

Document your current gearbox specifications, including ratios, mounting configurations, and any special materials needed for your operating environment. This information becomes crucial when discussing custom gearbox services with potential manufacturers.

Industry-Specific Considerations

Different sectors have unique demands that impact gearbox design. Steel mills require gearboxes that withstand extreme temperatures and heavy loads. Pulp and paper facilities need solutions resistant to moisture and chemical exposure. Cement plants demand durability against abrasive materials and continuous operation cycles.

Understanding your industry’s specific challenges helps identify manufacturers with relevant experience and proven track records in similar applications.

Key Capabilities to Look For

Not all custom gearbox manufacturers offer the same level of service or expertise. The best partners combine multiple capabilities under one roof, providing comprehensive solutions rather than just basic manufacturing.

Engineering and Design Expertise

Superior custom gearbox manufacturers employ experienced engineers who understand power transmission principles deeply. They should offer complete gearbox design services, from initial concept through final testing.

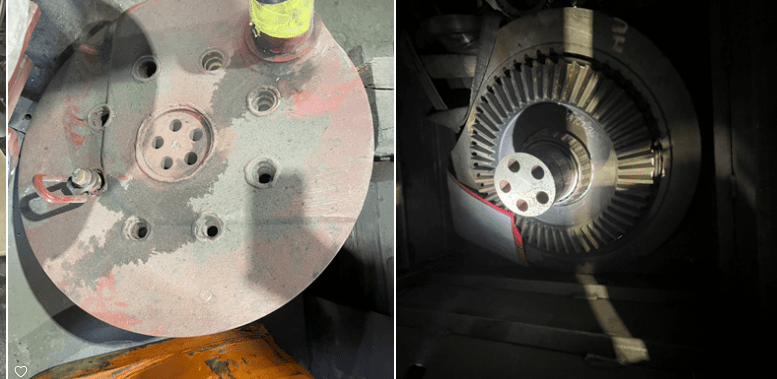

Look for manufacturers who can handle reverse engineering projects. When you need to replace obsolete gearboxes or improve existing designs, reverse engineering capabilities become invaluable. This skill demonstrates advanced technical competence and problem-solving abilities.

Manufacturing and Machining Capabilities

Custom built gearboxes require advanced manufacturing capabilities. Evaluate potential partners based on their machining equipment, quality control processes, and production capacity.

Large machine capacity indicates the ability to handle substantial projects without outsourcing critical components. Self-sufficient manufacturers maintain better quality control and faster turnaround times compared to companies that rely heavily on subcontractors.

Repair and Maintenance Services

The relationship with your gearbox manufacturer shouldn’t end at delivery. Ongoing support, maintenance services, and repair capabilities extend equipment life and minimize operational disruptions.

Emergency breakdown services represent a crucial differentiator. When critical gearboxes fail unexpectedly, rapid response capabilities can prevent minor issues from becoming major disasters. Manufacturers offering global breakdown response demonstrate commitment to customer support beyond normal business hours.

Evaluating Experience and Track Record

Experience matters significantly in custom gear manufacturing. Established manufacturers bring decades of knowledge about what works, what doesn’t, and how to solve complex challenges efficiently.

Industry Experience

Look for manufacturers with proven experience in your specific industry. A company serving mining, aggregate, and cement industries for decades understands the unique challenges these sectors face. They’ve likely encountered and solved problems similar to yours.

Ask for case studies, references, and examples of similar projects. Reputable manufacturers are proud to share their success stories and connect you with satisfied customers.

Global Reach and Local Support

While local presence matters for quick response times, global capabilities indicate established expertise and resource availability. Manufacturers serving clients worldwide have tested their systems and processes across diverse applications and environments.

Companies with both global reach and local support divisions offer the best of both worlds. You get access to extensive experience while maintaining close relationships with nearby support teams.

Quality and Manufacturing Standards

Quality control processes separate professional manufacturers from amateur operations. Understanding how potential partners ensure consistent quality helps predict long-term satisfaction with their products.

Quality Control Processes

Examine the quality control procedures each manufacturer follows. Professional operations implement systematic inspection processes, maintain detailed documentation, and follow established industry standards.

Gearbox inspection capabilities should include dimensional verification, material testing, and performance validation. Manufacturers who invest in comprehensive quality control typically deliver more reliable products.

Certifications and Standards Compliance

Industry certifications indicate commitment to quality and professional standards. While certifications don’t guarantee superior performance, they demonstrate systematic approaches to quality management and continuous improvement.

Ask about compliance with relevant industry standards for your application. Different industries may require specific certifications or compliance documentation.

Support Services and Response Times

Custom gearbox services extend far beyond initial manufacturing. The level of ongoing support significantly impacts your total cost of ownership and operational reliability.

Emergency Response Capabilities

Equipment failures rarely happen at convenient times. Manufacturers offering 24/7 emergency support provide valuable insurance against unexpected breakdowns.

Global breakdown response capabilities are particularly valuable for companies operating multiple facilities or international operations. Quick response times can mean the difference between minor repairs and major production losses.

Installation and Commissioning Support

Professional installation ensures optimal performance from day one. Manufacturers who provide installation, maintenance, and commissioning support demonstrate confidence in their products and commitment to customer success.

This support becomes especially important for complex custom applications where proper installation directly impacts long-term reliability and performance.

Cost Considerations and Value Assessment

While cost is important, the lowest price rarely represents the best value in custom gearbox manufacturing. Understanding total cost of ownership helps make informed decisions that benefit your operation long-term.

Initial Investment vs. Long-Term Value

High-quality custom gearboxes typically require larger initial investments but deliver superior value through extended service life, reduced maintenance costs, and improved reliability.

Consider factors like warranty coverage, expected service life, maintenance requirements, and energy efficiency when comparing proposals from different manufacturers.

Turnaround Times and Scheduling

Fast turnaround times can justify higher costs, especially for critical applications. Manufacturers with efficient processes and adequate capacity often complete projects faster than competitors struggling with resource constraints.

Schedule-driven manufacturers understand the importance of meeting deadlines and structure their operations accordingly. This reliability becomes particularly valuable for planned maintenance shutdowns and project schedules.

Making Your Final Decision

After evaluating potential partners across all these criteria, making the final selection requires balancing multiple factors specific to your situation and priorities.

Creating a Comparison Framework

Develop a systematic approach to compare your top candidates. Weight different factors based on their importance to your operation. Critical applications might prioritize experience and support services over cost savings.

Document your evaluation process to justify decisions to stakeholders and create a reference for future procurement decisions.

Building Long-Term Partnerships

The best custom gearbox manufacturer relationships evolve into strategic partnerships. Look for manufacturers who demonstrate genuine interest in understanding your business, not just completing transactions.

Partners who invest time in understanding your operations, challenges, and goals are more likely to provide valuable solutions and proactive support over time.

Finding Your Ideal Manufacturing Partner

Choosing the right custom gearbox manufacturer requires careful evaluation of capabilities, experience, and alignment with your specific needs. The best partners combine technical expertise with responsive service and commitment to long-term relationships.

EuroGear Industries exemplifies these qualities with over 60 years of experience serving demanding industries worldwide. Our Montreal-based engineering and manufacturing facility, combined with US divisions, provides both global capabilities and local support for comprehensive custom gearing solutions.

From emergency breakdown services to complex reverse engineering projects, we deliver the expertise and reliability your operations demand. Contact us today to discuss how our custom gearbox services can support your specific requirements and operational goals.