When machinery breaks down unexpectedly, every minute counts. The difference between a quick fix and weeks of costly downtime often comes down to one crucial factor: having the right gearbox solution for your specific application.

Custom gearboxes aren’t just about replacing what’s broken they’re about optimizing your entire operation for peak performance. Whether you’re running a mining operation in Saskatchewan, managing a pulp and paper mill in Ontario, or operating heavy machinery in Quebec, the right custom gearbox can dramatically improve efficiency, reduce maintenance costs, and extend equipment life.

At Euro Gear Industries, we’ve spent over 60 years perfecting the art and science of custom gearbox design and manufacturing. Our Montreal-based facility serves clients worldwide, from emergency breakdown situations to complex custom engineering projects. Let’s explore how custom gearboxes can transform your industrial operations.

Understanding Custom Gearbox Applications

Custom gearboxes serve as the backbone of industrial operations across multiple sectors. Unlike off-the-shelf solutions, custom built gearboxes are engineered to meet your exact specifications, operating conditions, and performance requirements.

Why Standard Gearboxes Fall Short

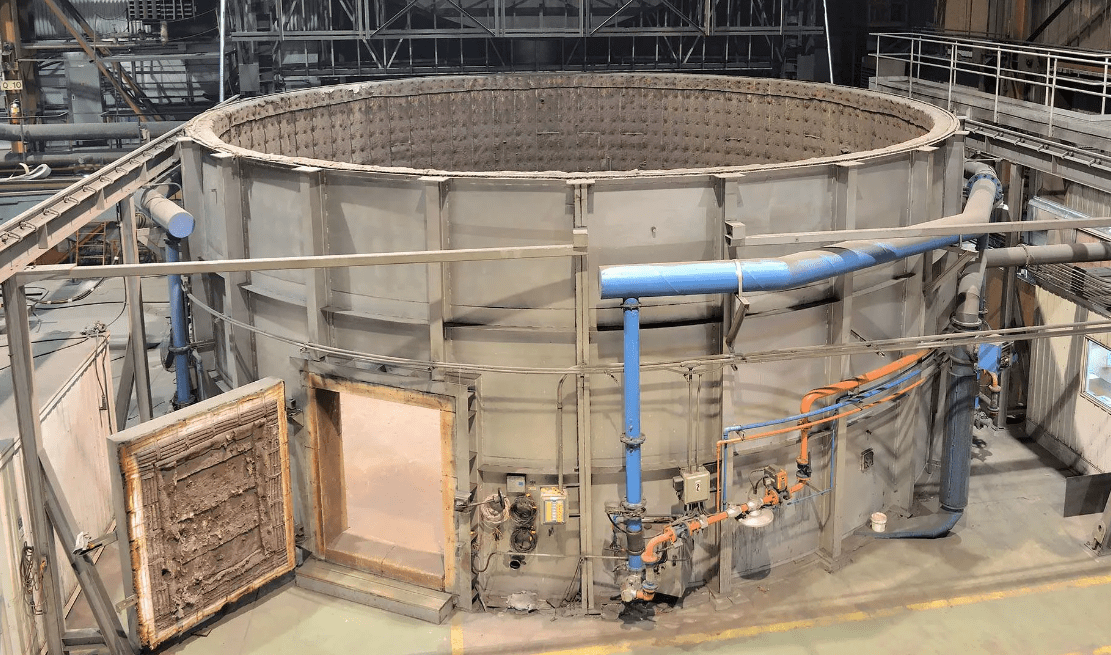

Standard gearboxes are designed for general applications, which mean they often lack the precision and durability required for specialized industrial environments. Mining operations face extreme conditions with heavy loads and continuous operation. Cement plants deal with high temperatures and abrasive materials. Hydro electric facilities require gearboxes that can handle massive torque while maintaining precision over decades of operation.

The Custom Advantage

Custom gearbox services in Montreal and across Canada focus on creating solutions that address these specific challenges. By working with experienced custom gearbox manufacturers, you gain access to:

Precision engineering tailored to your exact load requirements

Materials selected for your specific operating environment

Gear ratios optimized for your application’s speed and torque needs

Integration capabilities that work seamlessly with your existing systems

Engineering Excellence in Gearbox Design

Advanced Design Methodologies

Modern gearbox design in Montreal incorporates sophisticated engineering software and decades of field experience. Our engineers use advanced modeling techniques to simulate real-world conditions, ensuring your custom gearbox will perform reliably under your specific operating conditions.

The design process begins with a comprehensive analysis of your application requirements. We evaluate factors such as:

Operating speeds and torque requirements

Environmental conditions including temperature, humidity, and contamination

Space constraints and mounting requirements

Maintenance accessibility and frequency

Expected service life and reliability targets

Reverse Engineering Capabilities

Sometimes the best solution involves improving upon existing designs. Our reverse engineering services allow us to analyze your current gearbox, identify areas for improvement, and create an enhanced custom solution. This approach is particularly valuable for older equipment where original documentation may be unavailable or outdated.

Custom Gear Manufacturing Process

Precision Gear Cutting

Custom made gears in Canada require exceptional precision to ensure smooth operation and extended service life. Our Montreal facility utilizes advanced gear cutting equipment capable of producing gears with tolerances measured in thousandths of an inch.

The gear cutting process involves several critical steps:

Material Selection: We choose materials based on your specific application requirements, considering factors such as hardness, wear resistance, and fatigue strength.

Precision Machining: Our CNC equipment ensures consistent accuracy across all gear teeth, critical for smooth operation and minimal vibration.

Heat Treatment: Proper heat treatment optimizes gear strength and wear characteristics for your specific application.

Quality Control: Each gear undergoes rigorous inspection to ensure it meets our exacting standards and your specifications.

Custom Gearing Solutions for Specialized Applications

Different industries require different approaches to custom gearing solutions. Mining operations need gearboxes that can handle shock loads and continuous operation. Pulp and paper mills require systems that operate reliably in humid, corrosive environments. Steel mills demand gearboxes that can withstand extreme temperatures and heavy loads.

Our experience across these diverse industries allows us to apply lessons learned from one sector to challenges in another, resulting in more robust and reliable solutions.

Comprehensive Repair and Maintenance Services

Emergency Breakdown Response

When gearbox failures occur, production stops. Our global breakdown response service ensures you get back online as quickly as possible. With strategically located inventory and rapid response teams, we can often provide temporary solutions while permanent repairs are completed.

Our emergency services include:

24/7 technical support and consultation

Rapid assessment and diagnosis

Temporary repair solutions to restore production

Expedited manufacturing of replacement components

On-site installation and commissioning

Preventive Maintenance Programs

The best breakdown is the one that never happens. Our maintenance and support programs help identify potential issues before they become costly failures. Regular inspections, oil analysis, and vibration monitoring can extend gearbox life significantly while reducing unexpected downtime.

Montreal Gearbox Repair Services

Our Montreal facility serves as the hub for comprehensive gearbox repair services across Canada. Whether you need minor repairs or complete rebuilds, our experienced technicians have the expertise and equipment to restore your gearboxes to like-new condition.

Industry-Specific Applications

Mining and Aggregate Operations

Mining operations present some of the most challenging conditions for gearbox operation. Heavy loads, continuous operation, and harsh environments require specially designed solutions. Our custom gear manufacturing in Saskatchewan and Manitoba serves mining operations across Western Canada with gearboxes designed for reliability and longevity.

Power Generation

Hydro electric facilities rely on gearboxes that must operate reliably for decades with minimal maintenance. Our custom engineered gears for power generation applications are designed with redundancy and fail-safe features to ensure continuous operation.

Manufacturing Industries

From cement plants to steel mills, manufacturing operations require gearboxes that can handle varying loads while maintaining precise control. Our custom gearbox design and manufacturing in Ontario serves these diverse industrial applications with tailored solutions.

Quality Assurance and Testing

Rigorous Testing Protocols

Every custom gearbox undergoes comprehensive testing before shipment. Our testing protocols simulate real-world operating conditions to ensure reliability and performance. Load testing, vibration analysis, and temperature monitoring verify that each gearbox meets or exceeds specifications.

Continuous Improvement

Our commitment to quality extends beyond initial delivery. We maintain detailed records of gearbox performance and use this data to continuously improve our designs and manufacturing processes. This commitment to excellence has made us a trusted partner for industrial operations worldwide.

Global Reach, Local Service

While our engineering and manufacturing facility is located in Montreal, our service network extends globally. We maintain divisions in the United States and service clients around the world. This global presence allows us to provide local support while leveraging our centralized engineering expertise.

Our turn-key solutions and support services are designed to deliver industry-leading response times and quick turnaround. Whether you need emergency repairs, routine maintenance, or a completely new custom gearbox system, we have the resources and expertise to meet your needs.

Maximizing Your Investment in Custom Gearboxes

Investing in custom gearbox solutions pays dividends through improved reliability, reduced maintenance costs, and optimized performance. The key to maximizing this investment lies in working with experienced partners who understand both the technical requirements and operational realities of your industry.

Custom gearboxes represent more than just replacement parts they’re strategic investments in your operation’s future. By choosing solutions designed specifically for your applications, you gain competitive advantages through improved efficiency, reduced downtime, and lower long-term costs.

Ready to explore how custom gearbox solutions can transform your operations? Contact Euro Gear Industries today to discuss your specific requirements and discover why industrial leaders across Canada trust us with their most critical power transmission needs.